(1)(2)(1).jpg)

.jpg)

(4)(1)(1)(1)(1).jpg) There are many problem-solving techniques available to managers and most of them are powerful tools for reaching a solution. However, one stands out as the power tool to use for deciding ‘which’ problems to solve; ‘Pareto Analysis’. It sorts the vital few from the trivial many. It is also known as ‘80/20 rule’, suggesting that 80 percent of the effect comes from 20 percent of causes.

There are many problem-solving techniques available to managers and most of them are powerful tools for reaching a solution. However, one stands out as the power tool to use for deciding ‘which’ problems to solve; ‘Pareto Analysis’. It sorts the vital few from the trivial many. It is also known as ‘80/20 rule’, suggesting that 80 percent of the effect comes from 20 percent of causes.

For example, Pareto Analysis done for a company revealed that 10 percent of the customers accounted for 60 percent of sales and the bottom 80 percent of customers accounted for 25 percent of sales. This kind of analysis sets the mind of the management thinking about such issues as where to focus the energies of sales staff – whether to segment the customer base and how to service the various segments differently.

Pareto Analysis tells you which problem, if solved, will give the real bang for your buck. At the same time, it is a simple and easy tool to use. It is also flexible that it can be applied in almost any situation.

The tool is named after the Italian economist Vilfredo Pareto (1848-1923). (There is a controversy that the tool was created not by Pareto but by Joseph Juran (1904-2008), an American Management Expert, who named it after Pareto).

Steps

Pareto Analysis does not solve the problems but identifies which problems have the greatest impact. It thereby generates priorities for management action. Pareto Analysis involves a number of steps.

-

Add up the scores for each group – You can now add up the scores for each cause group. The group with the top score is your highest priority and the group with the lowest score is your lowest priority.

-

Score problems – Now you need to score each problem. The scoring method you use depends on the sort of problem you’re trying to solve.

-

Identify and list problems – First, write a list of all of the problems that you need to resolve. Where possible, talk to customers and team members to get their input and draw on surveys, helpdesk logs and suchlike, where these are available.

-

Identify the root cause of each problem – For each problem, identify its fundamental cause. (Techniques such as Brainstorming, the Five-Whys will help.)

-

Group problems together by root cause – Next, group problems together by cause. For example, if three of your problems are caused by lack of staff, put these in the same group.

-

Take action – Now you need to deal with the causes of your problems, dealing with your top-priority problem or group of problems first. Keep in mind that low scoring problems may not be worth bothering with; solving these problems may cost you more than the solutions are worth.

Note: This approach is great for identifying the most important root cause to deal with but doesn’t take into account the cost of doing so. Where costs are significant, you may use techniques such as Cost/Benefit Analysis to determine which changes you should implement.

Example

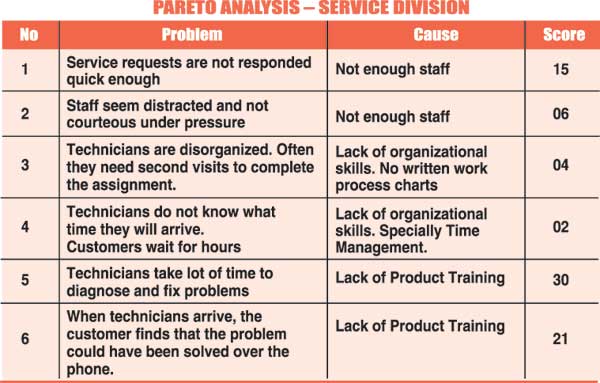

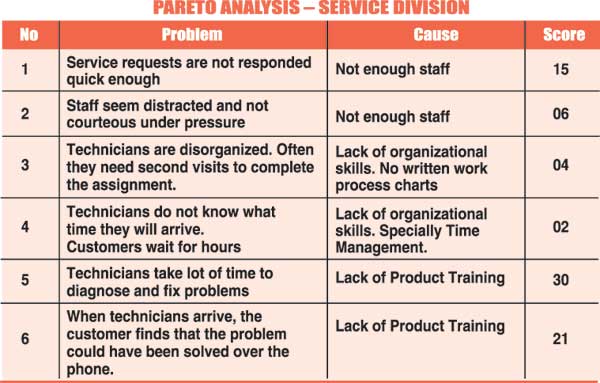

Jack has been requested by the company’s top management to take over the failing Service Division of the company, which was experiencing a host of problems that need resolving. His main assignment is to increase overall customer satisfaction. He went through the last three months’ records and decides to score each problem by the number of complaints that the division has received for each one. See the table. (You may also draw a pie chart for visual clarity)

Jack then groups problems together. He scores each group by the number of complaints and orders the list as follows:

1 Lack of product training – 51 complaints. (65 percent)

2 Too few Service Division staff - 21 complaints. (27 percent)

3 Lack of organisational skills – 06 complaints (08 percent)

As you can see, Jack will get the biggest benefits by providing staff with more product training. Once this is done, it may be worth looking at increasing the number of staff in the Service Division. It’s possible, however, that this won’t be necessary: the number of complaints may decline and training should help people to be more productive. He may also take action to arrange some training on organisational skills during corrective action.

By carrying out a Pareto Analysis, Jack is able to focus on training as an issue, rather than spreading his effort over training, taking on new staff members and possibly installing a new computer system to help engineers be more prepared.

There are a few risks in Pareto Analysis:

-

Ending up with things that are too-big to address.

-

Using measures which lead to the highest bar on the chart indicating something that is not the most appropriate item to address.

-

Selecting the wrong items, such as jumping to conclusions rather than using proven facts.

-

Assuming the people who are doing the measurement are motivated and able to do this.

-

Last-minute changes that are based on intuition rather than measurements and known facts.

Steps to avoid them:

-

Educate the people who are doing the measurements and check with their managers that they can do this extra work.

-

Take care to start with the right problem.

-

Remember that the focus is to find the most important item, so get measurements right.

-

Carefully consider the effort you will need to address the selected items. If this will be too much, then take another step to find a lower-level focus.

Be very careful when taking intuitive leaps. It is often better to trust a process which can later be verified.

Benefits of Pareto Analysis

-

Solves efficiently a problem by the identification, according to their importance, of the main causes of the faults.

-

Sets the priorities for many practical applications. Some examples are: process improvement efforts for increased unit readiness, customer needs, suppliers, investment opportunities.

-

Shows where to focus efforts.

-

Allows better use of limited resources.

Actions

Actions

Let us take two examples. In stock control, you frequently find an elaborate procedure for stock control with considerable paperwork flow because the systems and procedures are geared to the most costly or fast-moving items. As a result, trivial parts may cost a firm more in paperwork than they cost to purchase or to produce.

An answer is to split the stock into three types, usually called A, B and C. Grade A items are the top 10 percent or so in money terms while grade C are the bottom 50-75 percent. Grade B are the items in between. It is often well worthwhile treating these three types of stock in a different way leading to considerable savings in money tied up in stock.

Production control can use the same principle by identifying these vital few processes, which control the manufacture and then building the planning around these key processes. In quality control concentrating in particular on the most troublesome causes follows the principle. In management control, the principle is used by the top management looking continually at certain key figures.

Thus, it is clear that the Pareto concept – ‘the vital few and the trivial many’ – is of utmost importance to management.

(Lionel Wijesiri, a corporate director with over 25 years’ senior managerial experience, can be contacted at [email protected])

(1)(2)(1).jpg)

.jpg)

(4)(1)(1)(1)(1).jpg) There are many problem-solving techniques available to managers and most of them are powerful tools for reaching a solution. However, one stands out as the power tool to use for deciding ‘which’ problems to solve; ‘Pareto Analysis’. It sorts the vital few from the trivial many. It is also known as ‘80/20 rule’, suggesting that 80 percent of the effect comes from 20 percent of causes.

There are many problem-solving techniques available to managers and most of them are powerful tools for reaching a solution. However, one stands out as the power tool to use for deciding ‘which’ problems to solve; ‘Pareto Analysis’. It sorts the vital few from the trivial many. It is also known as ‘80/20 rule’, suggesting that 80 percent of the effect comes from 20 percent of causes.