Reply To:

Name - Reply Comment

For the first time in Sri Lanka, a small-scale gas turbine engine has been developed by a team of four final-year students of the Aeronautical Engineering Stream, Department of Mechanical Engineering, University of Moratuwa.

For the first time in Sri Lanka, a small-scale gas turbine engine has been developed by a team of four final-year students of the Aeronautical Engineering Stream, Department of Mechanical Engineering, University of Moratuwa.

This team belongs to the first batch of the Aeronautical Stream, which started several years ago in the university under the administration of the Mechanical Engineering Department.

H.D.V. Amarathunga, D.M. Annasiwatta, H.W.S. Dilanjaya and Y.A.M. Parakrama were able to develop this gas turbine engine under the guidance of Dr. Saliya Jayasekara, Senior lecturer and the coordinator of the Aeronautical Engineering Stream.

According to the available documentary evidence, this is the first ever gas turbine engine developed in Sri Lanka with locally-sourced materials and expertise. According to the novel gas turbine engine Dr. Saliya Jayasekara said: “As a government university, Moratuwa became the first university which started an Aeronautical Engineering Stream in Sri Lanka. In the first batch, a team of four students has a curiosity for design and development of a gas turbine. Hence, we were able to guide this team to take the project to a successful end.

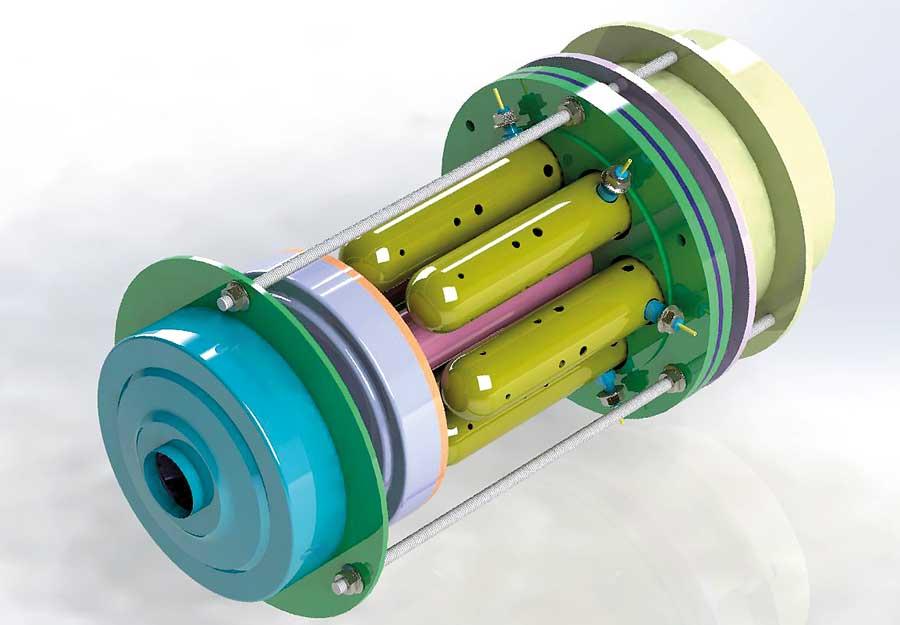

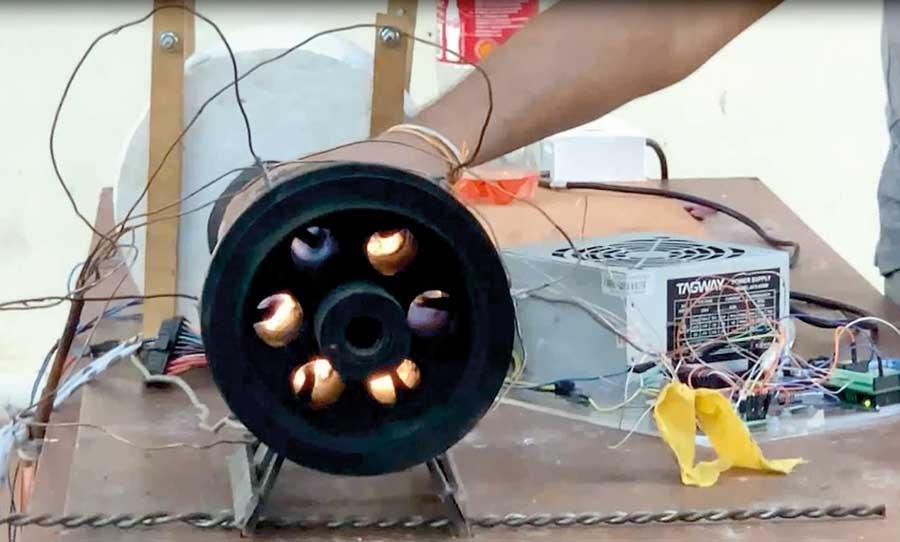

“In the engine, a centrifugal compressor is used to compress air into a cannula- type combustion chamber that contains six individual small combustors to facilitate a space for a complete combustion of fuel and air mixture. Then burnt gas is directed to a turbine rotor through nozzle guide vanes to generate sufficient power, which drives the compressor shaft assembly. Safe operation of the engine was the main concern of the group and they are the first known group which for the first time used a cannula-type combustion chamber in a micro gas turbine/turbojet.

D.M. Annasiwatta

Dakshaka Amaratunga

Malika Parakrama

Shenal Dilanjaya

|

Dr. Saliya .Jayasekara

|

A new fuel vaporization method was introduced to this engine marking an important innovation to the field. Currently we are engaged in another research project to improve this vaporization technique.

We mainly focused on the design and development of the engine using cost effective and feasible manufacturing methods that are available in Sri Lanka. Most parts of the engine were manufactured locally except the fuel injector, which is obtained from an old car while abandoned electronic parts from e-waste are used for the development of the engine combustion control circuit.

By developing the engine from scratch to a 3D design and a design model to the actual working prototype; this team has shown that they can achieve this milestone marking the first step in aviation designing and manufacturing industry in Sri Lanka with the minimum facilities and resources.

Currently, this engine is used for research purposes in the Mechanical Engineering Department. Finally, the academic staff of the department and the aeronautical engineering students expects to expand their capabilities and limits to develop this technology until this product can reach commercial level applications.’’ Dr. Jayasekara said.