Reply To:

Name - Reply Comment

By P.D.De Silva

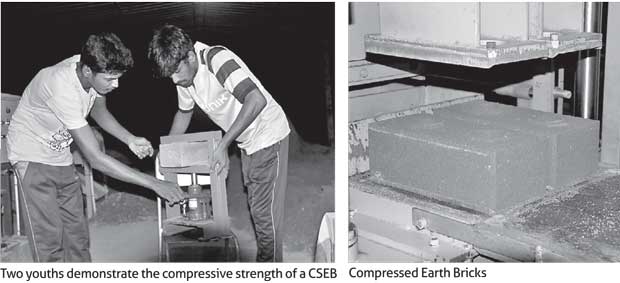

Strong, easy to build with, eco friendly, cool and affordable would be the best way to describe the compressed stabilized earth bricks (CSEB) manufactured by youth being trained by Projects For Youth (PFY) in Kithulewela Matara.

The bricks are manufactured by mixing ten parts of sieved earth with one part of cement and compressed into an attractive 12x6 x 4 interlocking block by a modern fully automatic hydraulic press at a rate of 900 bricks per hour. The compressed brick is cured for ten days and does not require kiln drying. Building with PFY’s compressed earth brick is fast as it does not require any bonding material or plastering.

Soil has been used for construction of shelters for thousands of years while Compressed Earth Blocks (CEB) or Compressed Stabilized Earth Blocks (CSEB) have been in use in South America in the 1950s and later on in the United States and other developing countries.

It was in 1970 the entrepreneur Fred Kumarapperuma ventured into the manufacture of CSEB by establishing Projects For Youth. It was after the 2004 tsunami that Caritas came to his assistance. As the demand for CSEB grew and needed more funding Fred was joined by five retired professionals namely Sarath Keerthi, Piyasena Samarathunga, Upul Kodippilli and J.K. Padmasiri after which the project was established at its present location.A few years ago a Dutch couple gifted the PFY with a high performance CESB press which is capable of producing 900 bricks

per hour.

The government should come forward to assist youth who master the manufacturing process to establish their own industries as Compressed Stabilized Earth Blocks are gaining popularity over kiln dried bricks or cement blocks and even the raw materials and manufacture is more eco friendly said Fred who may be considered a pioneer manufacturer of CSEB in Sri Lanka.