18 Feb 2021 - {{hitsCtrl.values.hits}}

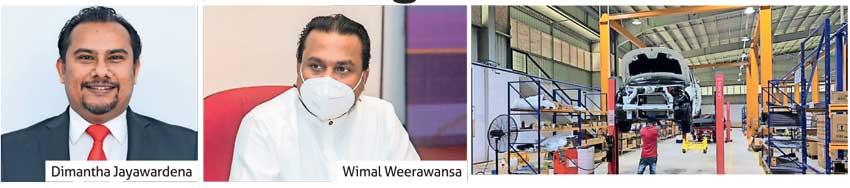

The Industries Ministry, spearheaded by Minister Wimal Weerawansa, is soon to launch the Standard Operating Procedure (SOP) for local assembly of vehicles and automotive component manufacturing, to encourage world-renowned brands to locally assemble vehicles.

Sri Lanka Automotive Component Manufacturers’ Association (SLACMA) President Dimantha Jayawardena said that the new SOP has been prepared in keeping with the highest standards around the world.

“This SOP has been prepared by the Policy Development Division of the Industries Ministry in close collaboration with the Finance Ministry, Sri Lanka Customs, Registrar of Motor Vehicles, Sri Lanka Automobile Assemblers and Automobile Component Manufacturers. With the launch of the SOP, it will become mandatory that vehicle assembly comply to the SOP and increase value addition for locally manufactured vehicles,” Jayawardena said.

The SOP includes guidelines and standards for registration at the Motor Traffic Department, BOI, Sri Lanka Customs and Industries Ministry and for the local assembly of vehicles.

It has also specified the necessary regulations for standardisation of the assembling and manufacturing process, the automobiles and components and the establishment of the assessment facilities. It further has guidelines for the exportation of assembled and manufactured vehicles and the recommended exemptions of excise duties.

stic market at the first stage and in order to achieve this objective, there should be a substantial level of investment in the domestically value-added automobile manufacturing/assembly industry, which could create the demand for locally manufactured components increasing their quality and to achieve internationally renowned standards,” Jayawardena said.

“This SOP includes all regulations, procedures and requirements related to different aspects of the industry, from the registration of an industry to the safety and quality standards applicable to the same and is subject to review and revision every five years. Prospective local assemblers should be given the flexibility during the first two years to invest and start operations and adhere to the SOP guidelines within a two-year time-frame,” he added.

The SLACMA expects more than 20,000 direct jobs and 25,000 indirect jobs to be created within the next two to three years. Currently the SLACMA is working with the Skills and Development Ministry together with the NAITA and German Tech to absorb these students to the local assemblies.

The advantage of local manufacturing of automobiles allows technology transformation and technical training under some of the world’s best manufacturing standards such as the Just In Time, 5S, KAISEN, LEAN Manufacturing, IATF 16949 and Six SIGMA standards. This will help our students to apply these manufacturing methods in other manufacturing industries.

20 Nov 2024 9 minute ago

20 Nov 2024 24 minute ago

20 Nov 2024 29 minute ago

20 Nov 2024 31 minute ago

20 Nov 2024 1 hours ago