16 Jul 2024 - {{hitsCtrl.values.hits}}

One of Calzedonia’s retail outlets, Intimissimi

In the face of global economic challenges, the apparel industry has struggled to maintain its footing. Yet, within this

|

Sandro Veronesi |

turbulent landscape, Italy has proven to be a significant export destination in the EU for Sri Lankan apparel.

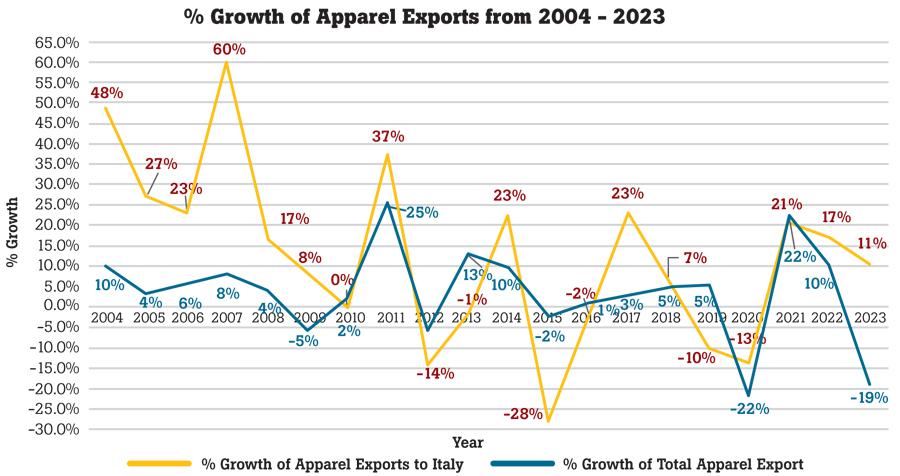

In 2013, Sri Lanka’s total apparel exports were valued at US$ 4.3 billion, with exports to Italy accounting for 9 percent or US$ 408 million. Ten years later, Sri Lanka’s total apparel exports saw a modest 5 percent increase to US$ 4.53 billion, while exports to Italy surged 38 percent to US$ 563.5 million, accounting for nearly 12 percent of Sri Lanka’s total apparel exports.

If the past 20-year period is considered, this growth is even higher; while total apparel exports from Sri Lanka to the world grew by 86 percent over the past two decades, exports to Italy have gone up by 658 percent. As a result of this growth Italy recently emerged as the largest buyer of Sri Lankan apparel in the European Union. This substantial growth relative to the wider industry highlights a unique success story, the lessons of which should not be overlooked.

For the Italian market, quality is everything. A single millimeter can make the difference between quality and rejection, as they highly value craftsmanship and quality in everything from sports cars to architecture and, of course, fashion.

Given that 90 percent of this revenue in the past year alone has been driven Omega Line Ltd, we believe there are important lessons from our journey that can be applied to the wider Sri Lankan apparel industry which could yield lucrative growth opportunities in Italy and other emerging premium markets across the globe.

Production floor at the Omega Line factory

How did Omega Line foster such close ties with the Italian market?

Our journey began when the Calzedonia Group first turned to Sri Lanka with the launch of Omega Line in 1999. Founded by Italian entrepreneur Sandro Veronesi, Calzednoia was established in 1987 and began to gain traction in the lingerie and intimate wear market by 1993.

At the time, the brand was sourced from Eastern Europe, but as it grew, they began to explore alternative options. At the time, many other countries were in the running, from the Philippines to Kenya and some nations in Africa. While there were many factors working against investment in Sri Lanka at that time, we were fortunate that Veronesi had a friend who was already manufacturing in Sri Lanka and, together with a few others, gave our country a positive recommendation. It was mainly based on this positive word of mouth about the work ethic, commitment, and trainability of our people that he first considered Sri Lanka.

At the time, the brand was sourced from Eastern Europe, but as it grew, they began to explore alternative options. At the time, many other countries were in the running, from the Philippines to Kenya and some nations in Africa. While there were many factors working against investment in Sri Lanka at that time, we were fortunate that Veronesi had a friend who was already manufacturing in Sri Lanka and, together with a few others, gave our country a positive recommendation. It was mainly based on this positive word of mouth about the work ethic, commitment, and trainability of our people that he first considered Sri Lanka.

With a great deal of effort from all parties, this one piece of good fortune turned into a US$ 350 million investment in our nation and Omega Line’s first factory in Sri Lanka. Starting with just 55 employees—of which I was the first—we grew together with Calzedonia. As they expanded from 300 sales outlets in 1999 to over 5,500 outlets across 55 countries today, we grew as well, and today, we have around 15,500 employees.

Within two years of establishing operations we grew with the launch of Sirio Limited in 2022. With it, we expanded our portfolio to basic underwear and beachwear to meet rising consumer demand. This initiative was followed in 2005 with the establishment of a dedicated plant for men’s briefs, further enhancing our capacity and market presence.

In 2007, we introduced Alpha Apparels, focusing on men’s briefs and t-shirts, diversifying our product offerings and consolidating our foothold in the apparel sector. Concurrently, we launched Benji, a facility for local production of underwear and bra cups, contributing to supply chain robustness and local economic development.

With the dawn of peace in 2013, we expanded to Vavuniya with the launch of a state-of-the-art facility employing over 2,700 individuals to further complement our increasing scale and support regional economic development. In the face of immense post-COVID volatility, we expanded our workforce by 25 percent.

At the core of this success has been a steadfast commitment to quality craftsmanship, innovation, sustainable and ethical manufacturing, and a sincere commitment to bringing out the best in our people, who ultimately are the bedrock of this remarkable success story.

For the Italian market, quality is everything. A single millimeter can make the difference between quality and rejection, as they highly value craftsmanship and quality in everything from sports cars to architecture and, of course, fashion

Current processors that surpass client expectations

Innovation has been a cornerstone of our success. In 2004, we successfully implemented a modular production system for the first time in Sri Lanka, reducing production lead times from 30-45 days down to just 7-25 days. The flexibility this enabled was crucial in meeting the demand for premium, high-quality apparel garments with small order quantities for the Italian market.

Sustainability is another core value at Omega Line. We aligned with the ‘Fashion Pact’ committing to carbon output reduction and environmental considerations. Our main factory utilises solar energy and is exploring further solar power options. Initiatives to incorporate recycled fabric and thread into our production processes are also underway, reinforcing our commitment to environmental responsibility.

Our digital transformation journey, leveraging emerging tech such as IoT and AI, aims to enhance operational efficiency and explore new opportunities. We have invested US$ 1.85 million in a photovoltaic plant generating approximately 2,300 kW of power, demonstrating our dedication to reducing carbon emissions.

Human capital has been integral to Omega Line’s success. In addition to direct training on their work, we also offer training on everything from motivational skills to personal finance management, effective communication, and even personal grooming, all of which are supplemented with overseas training programmes. These factors foster loyalty and a shared commitment to excellence, central to our value proposition of offering nothing but the best.

As we approach 2030, new EU guidelines and regulations present challenges and opportunities. Compliance with these regulations can position Sri Lanka as a preferred supplier, especially if we are prepared and proactive.

While in the short term, the market remains subdued, with some buyers stockpiling due to low orders last year, I am confident Sri Lanka will continue to shine in the global apparel industry, particularly in our cherished partnership with Italy.

This growing love affair is not a happy accident, but rather is the result of strategic investments, a steadfast commitment to quality, and a relentless pursuit of innovation and sustainability. The future holds promising prospects for further growth and collaboration. As Sri Lankans with such great talent, technological capabilities and an eye for high-quality detailing, we believe that nothing is impossible for our people, so long as we commit to decisive action.

Sri Lanka should capitalise on its strategic advantages and strong market potential to attract investment from key markets such as Germany, the Netherlands, and Holland

New opportunities for partnerships built on shared excellence

Looking forward, Sri Lanka should capitalise on its strategic advantages and strong market potential to attract investment from key markets such as Germany, the Netherlands, and Holland. These countries represent lucrative opportunities for collaboration and growth, provided our Government is proactive in creating an attractive investment climate. Infrastructure development and regulatory reforms to improve the ease of doing business and incentivize foreign investors will be pivotal in enhancing Sri Lanka’s appeal as a preferred destination for industrial investment.

By leveraging our robust manufacturing capabilities, skilled workforce, and strategic geographic location, Sri Lanka can emerge as a hub for manufacturing excellence and innovation in the apparel sector.

We must also learn lessons from the notable instances when we lost manufacturers genuinely interested in establishing production facilities in Sri Lanka simply as a result of bureaucratic inefficiencies, red tape and corruption. We need to ensure such obstacles are totally eliminated to create an enabling business environment.

Apparel is one of the markets we work closely with in Italy, but many other industries are still not tapped into. For example, approximately 118,000 Italians visited Maldives in 2023; we only received 22,000.

Similarly, in the fisheries and aquaculture sector, Sri Lanka’s share in the Italian market is a mere 0.27 percent, indicating significant room for growth. The potential in the Italian market and across the EU, and even in emerging markets closer to home is much more than we realize.

To bridge this gap, we need a concerted effort from all stakeholders to engage more strategically with our institutional and industry counterparts and directly with consumers in Italy, and all other emerging markets to strategically showcase all that Sri Lanka has to offer.

(The writer is the Chief Executive Officer and Managing Director of Omega Line Ltd and Deputy Chairman Joint Apparel Association Forum)

26 Nov 2024 6 hours ago

26 Nov 2024 7 hours ago

26 Nov 2024 8 hours ago

26 Nov 2024 9 hours ago

26 Nov 2024 9 hours ago