29 Aug 2023 - {{hitsCtrl.values.hits}}

By Chaturanga Pradeep Samarawickrama

Charcoal production in a country could be a major source of energy, but it also stirs controversy as its association with deforestation and adverse environmental impacts.

Charcoal production in a country could be a major source of energy, but it also stirs controversy as its association with deforestation and adverse environmental impacts.

The charcoal from wood is produced by heating it at a high temperature in a closed space without oxygen; the process known as “Anaerobic Heating.”

In this process, the wood becomes bone dry at 100°C, and a further rise in temperature to 300°C initiates pyrolysis. By doing so, the wood is broken down into water vapour, gases, wood acids and tars, with the evolution of heat resulting in charcoal.

The Daily Mirror investigation team visited the southern part of the island-known as the Arambekema village, which belonged to Kahakurullanpalassa Grama Niladhari Division of Thanamalvila Divisional Secretariat of Monaragala District- together with the team attached to the Centre for Environmental Justice (CEJ).

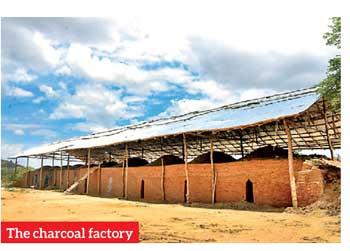

The team visited the area to inquire into the harm caused to the environment by a charcoal factory, which is operated by a Chinese business concern.

During the Daily Mirror’s visit to the place, the people belonging to several organizations in the village, got together and launched a protest against the alleged illegal charcoal production.

N.M.S.H. Premarathne, the leader of the village organizations, recently brought to attention this concerning issue.

According to concerns raised by him, a private company entered the village and initiated an unauthorised charcoal production venture within the buffer area of the Udawalawe Forest Reserve.

Premarathne expressed his concerns that if this venture continued, the Arambekema village may soon face the risk of turning into a barren land.

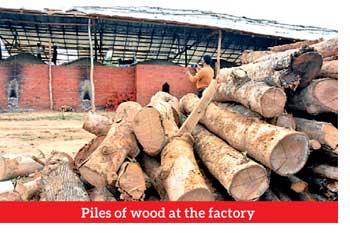

The company in question has been indiscriminately felling trees in the area to sustain its charcoal business.

The company in question has been indiscriminately felling trees in the area to sustain its charcoal business.

Furthermore, it has come to light that the land where their ovens were constructed is owned by an individual who possesses ‘Swarnaboomi’ deeds.

These developments have raised significant concerns among our village community.

Premarathne has claimed that not only were 20 ovens already established for charcoal production, but additionally there are plans to build 19 units in the same area to increase production.

Each oven consumes 4 1/2 tons of timber to produce one ton of charcoal.

This alarming situation involves the heat generated from burning logs being transmitted to the ground; which poses a threat to the surrounding trees, plants, and crops.

“To address this issue, we have taken immediate action by reaching out to various government institutions, including the Public Administration Ministry, Grama Niladhari, Thanamalvila Divisional Secretariat, and District Secretariat,” he said.

“To address this issue, we have taken immediate action by reaching out to various government institutions, including the Public Administration Ministry, Grama Niladhari, Thanamalvila Divisional Secretariat, and District Secretariat,” he said.

“By informing these authorities, we aim to bring attention to this matter and seek the necessary assistance and intervention to mitigate the potential ecological impact on our village.

“We understand the importance of preserving our environment and ensuring the well-being of our community.

“We are sure that this project has received a political sponsorship. Otherwise, Chinese people would not be able to start this kind of company on their own.

“This company was launched in the first quarter of this year, with claims being made that it was collecting wood that had fallen and broken. That was why people weren’t concerned about this project. Later, the people found out that large trees like Teak, Satinwood, Burutha and Neem had been taken out of the woods for charcoal production,” he said.

During the media visit to the charcoal production oven complex the manager of Tree Tec Trading (Pvt) Ltd.- who introduced himself as Factory Manager Sajith-had the opportunity to engage in a discussion with the media representatives.

During the media visit to the charcoal production oven complex the manager of Tree Tec Trading (Pvt) Ltd.- who introduced himself as Factory Manager Sajith-had the opportunity to engage in a discussion with the media representatives.

Sajith revealed that their company had initiated a programme to convert wood into charcoal to export it to various countries.

He assured that they had brought wood (not logs) from the State Timber Corporation in Udawalawe regional office.

As the manager claimed, the Timber Corporation has given the assurance to use invasive plants like Katu Andara, Maha Andara, Katupila, and Kurumanna for charcoal production.

“Our company has signed an agreement with the Department of Wildlife Conservation to get as many invasive plants as needed for production. He claimed that currently, they have purchased Rs. 1.8 million worth of timber to start the process,” Sajith said.

“There were two Chinese nationals, who are involved in the technical aspects of the factory. The manufactured charcoal is exported to China, Korea and Japan. Later, the charcoal will be exported to other countries as well,” the Manager said.

“This brings a better dollar income to the country. The country gets 60 per cent of the revenue while the export companies receive 40 per cent of the revenue. This is operated as a BoI project, and we have all the relevant documents to prove that this company has registered with this state institute,” he said.

“ Our company didn’t know that the structure was made in the buffer zone of the Udawalawe Forest Reserve. After some time, the Department of Wildlife Conservation came and informed us. Later, the company signed an agreement after the oven complex was made,” explained Sajith.

Our company didn’t know that the structure was made in the buffer zone of the Udawalawe Forest Reserve. After some time, the Department of Wildlife Conservation came and informed us. Later, the company signed an agreement after the oven complex was made,” explained Sajith.

He claimed that the people in the Arambekema village used to supply timber for the process. They used to supply trees like Neem to season the ovens.

“We have explained to the villagers not to bring the wood, which the company does not require for the process. But people used to bring various types of wood to us and tell us to buy from them. According to the legal framework that we have, we are unable to use trees like teak, satinwood, burutha, and neem, but we took some of them as the villagers forced us to.

“The Wildlife Commissioner General also said that he would grant permission to continue with the process in the buffer zone,” the Factory Manager said.

“Before starting the project, we did not get the Environmental Impact Assessment (EIA) report, but after building this structure, we managed to receive our report. Even though the Grama Niladhari of the area was informed, that official did not come to inspect the area. But later, he came to the area after receiving complaints from the villagers.

“We still haven’t received the Divisional Secretariat certificate, but we have started the process. Earlier, we informed the relevant government authorities about the production of charcoal. They had no idea about it. Later, we decided to launch the factory in this area.

“We have a factory with the same structure in Avissawella and soon after three months of launching the Avissawella factory, we decided to start another one here.

However, the Department of Wildlife Conservation agreed to provide the required timber to meet our targets,” the Factory Manager said.

The Chief Monk of the village and area Ven. Dampahala Ariyawansa Thera also commented on the issue. He said that the charcoal production factory should be stopped with immediate effect. He requested the relevant personnel and relevant authorities not to politicise this situation to meet their needs. “Do not put this issue on the agenda of any political party,” the priest said.

The Thera requested responsible persons to take immediate action to remove the factory from their village, as it was harmful to the village environment and the animals in the woods.

When the Daily Mirror contacted the BoI one of its senior officials confirmed that no approval was granted to proceed with the charcoal production in the Arambekema village. The official also said that no such company as Tree Tec Trading (Pvt) Ltd was registered with the BoI.

The State Timber Corporation (STC) also confirmed that they had not given permission for such a company to provide unlimited timber for charcoal production.

The Department of Wildlife Conservation and the Forest Department also confirmed that they had not given permission for such a company to engage in charcoal production.

Pix by Nimalsiri Edirisinghe

24 Nov 2024 49 minute ago

24 Nov 2024 2 hours ago

23 Nov 2024 23 Nov 2024

23 Nov 2024 23 Nov 2024

23 Nov 2024 23 Nov 2024