19 Jul 2018 - {{hitsCtrl.values.hits}}

Oil palm is being played out as a big issue on the sustainability agenda in our country now. Despite repeated best efforts by responsible stakeholders including growers, agri experts, academia etc, in refuting irrelevant allegations, the topic keeps arising – the latest of which is the media pick up alleging that oil palm cultivation is to replace rubber, arguing that oil palm development programme is a threat to the rubber industry and environment.

Oil palm is being played out as a big issue on the sustainability agenda in our country now. Despite repeated best efforts by responsible stakeholders including growers, agri experts, academia etc, in refuting irrelevant allegations, the topic keeps arising – the latest of which is the media pick up alleging that oil palm cultivation is to replace rubber, arguing that oil palm development programme is a threat to the rubber industry and environment.

Professor Asoka Nugawela explains the reality, backed by scientific data and evidence to refute allegations that are being plied to media. At the outset let us understand that government has clearly established a policy to expand the existing oil palm extent in the country to a maximum of 20,000 ha to substitute oil and fat imports. To achieve the 20,000 ha target of the government, around 11,000 ha of oil palm will need to be planted newly. Articles stating “oil palm to replace rubber” gives a false impression that oil palm would replace the entire rubber extent of the country; hence the need to set the record.

Environmental concerns

One scientific factor identified is that the water transpiration of oil palm plants increases from 5.5 to 7.5mm/day during drought periods whereas in rubber it decreases from 4.5 to 2.5 mm/day. The response to drought by the rubber plants is scientific but not that of oil palm.

Water transpiration under drought periods, i.e., when the soil water is generally depleted, cannot increase unless the plants are irrigated. Lee Chin et al., (2013) based on a long term lysimetric study that is yet in progress at FELDA, Malaysia reported that under dry weather, but under irrigated conditions, the water transpiration (potential evapotranspiration) of mature oil palm could increase up to 6.5 to 7.5mm/day.

It is common knowledge that water transpiration cannot be higher under drought conditions when soils are depleted of moisture. Under such stressful environmental conditions the stomatal pore size of leaves in whatever plant species are reduced.

The stomata of plants play a key role in plant water relations and under water stress conditions the plants reduce their stomatal pore size to control the water loss from the plants through transpiration. This change in stomatal pore size of plants is triggered by plant hormonal action. If not for this mechanism found in plants they would succumb to water stress conditions. Based on such un-scientific thinking it cannot be concluded that oil palm consumes water to the extent to create water shortages in oil palm cultivated areas.

Our national production of natural rubber is in a declining trend and in 2016 it stood as 79.1 thousand MT. National yield is as low as 800 kg/ha/year

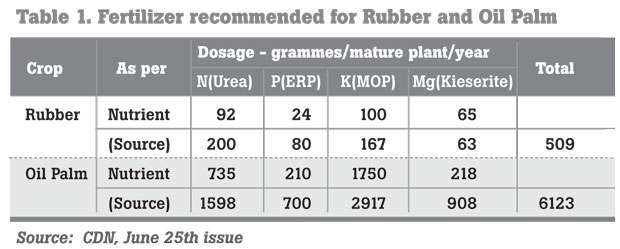

There is a misconception that high quantities of nutrients, i.e., more than ten times, are added to oil palm plantations in the form of chemical fertilizer when comparing with rubber (Table 1).

According to Table 1, the amount of chemical fertilizer recommended for a mature rubber tree per annum by the Rubber Research Institute (RRI) of Sri Lanka is generally in the region of 509g whereas for oil palm it is 6,123g, as per statistics from Coconut Research Institute. However, there is no blanket recommendation to give 509g of fertilizer per mature rubber tree per year by RRI. Even with soil and foliar analysis based fertilizer recommendation, there is no such standard quantity to be applied to a tree throughout its economic life span. The mixture and quantities recommended generally differ from field to field as it is intended to be and within a field too, once every three years if there are changes in the soil and foliar nutrient levels. If 509g per tree per year is taken as an average dosage inclusive of last six years of the economic cycle where no fertilizer was applied, then the corresponding dosage for oil palm has to be taken for comparison. Similarly, if it is assumed that certain mature rubber trees will not be fertilized due to not been productive, why is the same logic not applied to oil palm?

If the fertilizer usages of the two crops are to be compared on the basis of soil and foliar recommendations, then the comparable soil and foliar recommended dosage should be taken for the oil palm crop as well. With a soil and foliar analysis based fertilizer recommendation for oil palm the current recommended dosage of 6,123g per palm would definitely be reduced. Oil palm cultivators in Sri Lanka have therefore already taken initiatives to adopt soil and foliar based recommendations in their oil palm plantations. Progress on this is slow mainly due to the lack of a dedicated research institution to provide technical support for this crop.

Twenty thousand hectares of oil palm in Sri Lanka has the potential to save valuable foreign exchange moving out of the country

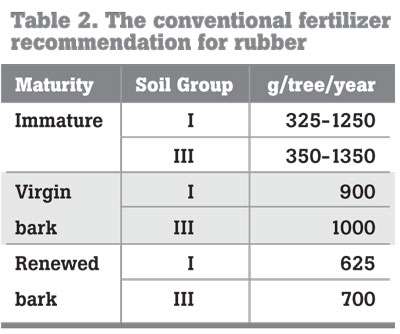

In the absence of soil and foliar based fertilizer recommendations for oil palm right now, a fair scientific approach to compare the relative nutrient need of the two crops would be to take the conventional mixtures and dosages recommended for both crops. A summary of the conventional fertilizer mixtures recommended for rubber by the Rubber Research Institute is given in Table 2.

In table 2, only the fertilizer usage during mature phase of the crops has been compared. However, to do a fair comparison of the fertilizer usage of the two crops, the dosage recommended for the entire life span has to be considered. On comparison, fertilizer usage per hectare of oil palm is only around twice the quantity recommended for rubber and not 10 times.

It is also claimed that the chemical fertilizer needed for rubber plantations is less due to nutrient recycling through the defoliation and re-foliation process of this deciduous type plant species. Generally nutrient recycling happens in both deciduous and non-deciduous type of plant species. The difference lies in that deciduous plants all leaves are shed simultaneously whilst in non-deciduous plants, leaves are shed as and when a leaf becomes non-contributing to the growth of the plant.

This happens when the respiration rate of leaves become higher than the photosynthetic rate either due to aging, diseases or physical damages. Hence nutrient recycling occurs in oil palm plantations as well. However, in oil palm the old non-contributory fronds are systematically removed through an important agricultural practice named frond management. They are methodically stacked within the plantations as mulch for soil, moisture conservation and for nutrient recycling.

In addition to the fronds, the solid wastes generated from the oil palm processing factories, i.e., empty fruit bunches and remnants of the mesocarp of fruits are added to the plantations to improving soil physical and chemical properties. To argue that rubber plantations recycle nutrients whereas oil palm plantations do not is non-scientific.

With nutrient management strategies together with soil and moisture conservation practices in place there is no way that the soil in oil palm plantations get degraded to the extent that replanting cannot be undertaken. Successful oil palm replanting’s with no signs of growth retardation could be seen at Nakiadeniya Estate where second generation oil palm plantations exist. We need to understand that soil degradation reported in any plantation is not the fault of a particular crop or plant species, but perhaps due to bad agricultural practices carried out by the relevant management.

A common concern is that effluents released by oil palm factories amount to nearly 75 percent of the weight of fresh fruit bunches and are highly toxic to animals. In oil palm fruits, the oil extraction rate and hence the oil content is around 22 to 23 percent of the fresh weight and the balance goes as waste material. However, the empty fruit bunches and the milled mesocarp is used in the plantations as soil amendments. Further, the shell of the nut is used to generate renewable energy to power the factories. All oil palm factories are self-sufficient in its energy requirement and therefore not dependent on the national grid for the same. Out of the 75 percent waste material, the majority are used productively and in an environmentally friendly manner. Since, no chemicals are used during the processing, the effluent coming out of oil palm factories will consist of only natural compounds/products bio-synthesized by the palm.

Such natural compounds/products, i.e. fats, carbohydrates, sugar, proteins and amino acids are being treated using conventional waste water treatment plants to prevent bad smell odor emanating if released to the environment un-treated. Also, since oil extracted from it is consumed by human beings it is highly unlikely that effluent would contain toxic compounds to harm any other animals.

A scientifically established fact is that palm oil, which is rich in vitamin E is the most accepted ingredient, being used globally in the manufacture of skin and hair creams. In Sri Lanka there have been random claims that dogs who have consumed ripe oil palm fruits have shed their coat of fur. There is no scientific proof which links consumption of oil palm fruits to shedding of fur.

Impact on natural rubber industry and way forward

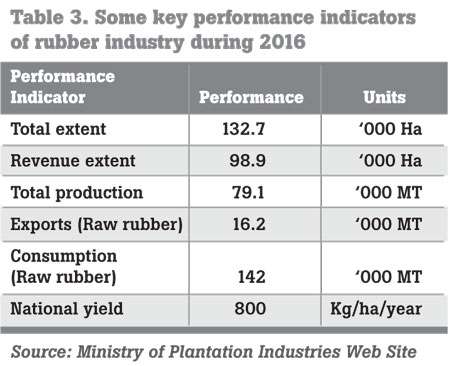

In addition to the environmental allegations, let me clarify concerns about depleting natural rubber production and its impact on the lucrative rubber product manufacturing industry in the country. Declining natural rubber production in the country is a serious issue for which interventions are needed. But, is the intervention alternative to prohibit the growth of another industry, vital for the economy of the country? I do not think it’s the correct strategy but any how let us analyze some key performance indicators of the natural rubber industry (Table 3) to find out what should be the correct interventions are.

Our national production of natural rubber is in a declining trend and in 2016 it stood as 79.1 thousand MT. National yield is as low as 800 kg/ha/year. With low land productivity, the cost of production of natural rubber will be so high that plantation companies will not be making returns on investment on rubber lands. Negative cash flow scenarios created in this background will further reduce essential inputs to rubber plantations worsening the situation. It leads to a vicious cycle.

However, this scenario is not new and had being in existence even during pre-privatization era as well. Also this declining trend in land productivity is true for other plantation crops like tea and coconut. At national level there should be a concerted effort to develop short, mid and long term strategies to arrest this declining trend in the plantation sector. In addition the experts in the industry, genuinely concerned about the negative growth of the industry can share their knowledge to turnaround the trend.

The plantation sector needs to be viewed holistically. A diversification strategy of crops bringing in a high Return on Investment (ROI) is the logical process. Oil palm and cinnamon fall into the high ROI category and hence investing in such crops is a no-brainer. If trading is poor in some crops the other crops would compensate.

An ‘expert’ of a particular crop should evolve into an agri-expert that understands trends and advocates the big agri picture and the benefits that plantation companies and the country could accrue. A plantation would be financially much stronger with a relatively higher number of crops rather than just one or two.

For average land productivity of rubber to be 800 in our country, the range should be around 500 to 1200 kg/ha/year. The government intention is to expand the oil palm extent by a further 11,000 ha to make the current extent of around 9,000 ha to 20,000ha. For this diversification program the poor performing rubber lands with lowest productivity levels will be used. If 11,000 ha of 500kg yielding rubber lands are converted to oil palm over a period of say four years, by planting 2,750 ha per year the immediate loss of rubber production will be around will be 1.4 thousand MT (500kg * 2,750ha). This is only 1.8% of our current national production and only about 0.9% of our current domestic consumption. Can this level of drop in natural rubber production due to expansion of oil palm cultivation in the country be a huge threat to the rubber products manufacturing industry in the country?

In Sri Lanka the use of rain guards to overcome crop losses due to interference of rain on harvesting and adoption of low frequency tapping to overcome issues related to harvester shortages are at a very low level. The two factors identified above contribute to around 40 percent loss of crop annually. If we recover this crop loss in at least 50 percent of the country’s total rubber revenue extent the national production could be increased by 15 thousand MT in a year, which is about 19 percent of our current national production or around 11 percent of our current domestic consumption.

Our vision should be to not depend on any country for our raw rubber requirement. We should adopt strategies like improved land productivity and increasing extent to meet our national targets. Certain plantation companies have demonstrated global leadership in managing rubber plantations. They should be motivated to take forward their business plans rather than enforcing restrictions. It is said that the private sector is the engine of the growth and development of a country; they must be allowed to progress uninhibitedly and be the standards and benchmarks for driving the plantation industry forward.

Productivity and yields

Low land productivity of oil palm in our Country remains an issue. Our national yield is around 18,000 kg/ha/year whereas the potential is 30,000 kg/ha/year. Through enhanced land productivity the revenue generated from this crop could easily be doubled so that cash flow improves and is ploughed back on currently poor performing crops like tea and rubber.

Whatever the crop, we need to achieve potential land productivity levels and thereby maximize earnings. Never ever wait for high NSAs’, which is determined elsewhere and for which we do not have any say.

Other concerns of oil palm

Oils and fats derived from oil palm crop have a wide range of applications. Apart from being used for cooking purposes, it is used to manufacture almost 40-50 percent of goods available in a super market to-day. Bakery products, confectionaries, chocolates, biscuits, noodles, milk powder, soaps, detergents, skin and hair care creams and oils, margarines and some medicines are a few examples.

Oils and fats derived from our coconut industry and imported to the country as palm oil are used for the production of all these goods. The reality is that we are even struggling to meet the coconut requirement to obtain coconut milk necessary for our day to day cooking purposes.

For whomever that vocalizes unknowingly that the trunk of oil palm does not have any uses, one has only to visit the web site of Malaysian Oil Palm Board to be exposed to the value of the oil palm trunk. In Sri Lanka once the oil palm industry develops and when there is sufficient number of uprooting fields it would definitely create an opportunity for investments. And by the way, molgas or pestle used for pounding of rice cannot be made out of palm oil trunk. If this is a worry, let the reader rest assured that our local pestle is made of the Kithul palm trunk, rather than any other tree.

Potential and realities

Twenty thousand hectares of oil palm in Sri Lanka has the potential to save valuable foreign exchange moving out of the country, improve the financial performance of plantation management companies and to upgrade the livelihood of plantation workers.

Environmental degradation that is talked about is not due the crop but due to bad practices adopted during cultivation in other countries like Indonesia where virgin forests are cut for this purpose. If someone argues that by converting less than 3 percent of the existing land extent under plantation crops (around 700,000ha) to oil palm which would consume an additional 10-15 percent of water would result in a situation where we will have to import water- it is a gross exaggeration. Malaysia, with its humungous extents of oil palm for the last 100 years, should be importing water from a long time ago. In reality Malaysia exports water to Singapore.

(The writer is Chair Professor, Department of Plantation Management, Faculty of Agriculture and Plantation Management, Wayamba University of Sri Lanka)

17 Nov 2024 17 Nov 2024

17 Nov 2024 17 Nov 2024

17 Nov 2024 17 Nov 2024

17 Nov 2024 17 Nov 2024

17 Nov 2024 17 Nov 2024