26 Jun 2018 - {{hitsCtrl.values.hits}}

During the past few weeks, there were reports in the local press that some of the rubber estates under the management of plantation companies are being converted to oil palm plantations.

During the past few weeks, there were reports in the local press that some of the rubber estates under the management of plantation companies are being converted to oil palm plantations.

From my personnel opinion as the longest served former Director of the Rubber Research Institute of Sri Lanka, when scientific factors affecting the environment and the best performing rubber end products manufacturing industry in the country are considered, this is a dangerous decision taken by the authorities, without taking the environmental impact and the economic impact of this crop diversification.

In most of the rubber estates under private management, as I have highlighted in my earlier press reports, and at the CRT seminar organized by the ministry of Plantation Industries, large extents of revenue areas of rubber estates have been ruined by over tapping and stimulation, totally ignoring the commendations of the RRI. There is no alternative for the planters in charge of those estates now to overcome this problem without replanting them at a very high cost.

Even the scientists of the RRI have reported that, in most of the plantations under private management, nearly 50 percent of the trees of ages between 10 to 15 years are already either tapping panel dried or totally tapped out. This is purely due to over exploitation. This is a disaster in the rubber plantations today and converting such clearings into oil palm in order to overcome this problem created by bad management is asking for more trouble. It would definitely put the rubber-based value added product industry, which earns over US $ 1.25 billion to Sri Lanka annually, in deep trouble.

Of the agricultural products of Sri Lanka, rubber is the only commodity that is converted into a reasonable value added products. It provides employment to over 30,000 skilled workers of the country while earning a reputation for Sri Lanka as a producer of world-recognized end products such as solid tyres, examination and surgical gloves, rubber flooring, engine components and footwear.

At present, Sri Lanka imports nearly 55000 Mt of raw rubber and latex annually from Asian countries to cater to the rubber products industry, as our rubber annual production has fallen to about 69000 Mt in 2016, compared to 130,000Mt produced a few years before that.

Competing with rubber industry giants

Can we continue to import raw rubber in to Sri Lanka in the future competing with the giants in the rubber products industry in the world, namely China the largest consumer, India the 3rd largest and Japan the 4th largest consumer, when there is a competition for raw materials in the Asian rubber market? How many of you are aware that 75 percent of the total NR production in the world is consumed in Asia now? That is why we have been requesting authorities to grow more rubber in the country including intermediate and dry zone as well.

It is true that palm oil is imported to meet the shortfall of edible oils in the country. Out of the 160,000 Mt of edible oil that Sri Lanka needs annually, coconut oil provides only about 55,000 Mt and the balance requirement is met by imported vegetable oils, mainly palm oil. Nobody knows the real quality of the vegetable oils imported to the country. There was a misconception in mid nineteen eighties that coconut oil is harmful to human health. That was a problem associated with coconut oil extracted and purified by improper rash methods. Due to that, the formation of Poly Aromatic Hydrocarbons (PAH) during the drying of coconut kernels at high temperature in kilns or during bleaching of crude oil extracted from contaminated and discoloured copra at high temperature using chemicals is unavoidable.

Fortunately, the scientists in Sri Lanka have been able to find a method to eliminate this toxic PAH formation by drying copra at low temperature using a drying chamber and also without using chemicals for bleaching, because coconut oil thus produced is white in colour and hence bleaching is not necessary. This health-safe product is now available in the market as physically extracted coconut oil.

They have even been able to change SLS standards of edible coconut oils by introducing new parameters such as maximum PAH value and peroxide values to convince the European and US consumers that our physically extracted coconut oil is the safest edible oil in the market. Earlier, heart patients were not allowed to consume coconut oil because of the presence of PAH, and due to its high LDL value.

Healthiest edible oil in market

But, today Europe and the US have accepted properly extracted coconut oil as the healthiest edible oil in the market and as a result; all Kentucky food outlets in UK and US have reverted back to the use of coconut oil. Based on this development, in addition to its use for edible purposes, it finds use even in pharmaceutical industry. Even in the GPN spray recommended as the first aid for heart patients before reaching a hospital, cleanly extracted coconut oil is used as the solvent because medium chain tryglycerides in coconut oil have the ability to supply oxygen to the brain fastest. Palm oil is substituted in cooking oils, either to bring the price down, or as a cheap oil substitute, but not due to any health benefits of it. Also the use of crude palm oil is restricted to mix with edible oils. However, I am not suggesting that palm oil imports should be restricted or the expansion of oil palm plantations in the country should be stopped; but, based on the above technical facts, none of the rubber estates in the South of Sri Lanka should be converted to oil palm or to any other crop because they are low yielding. If they are not meeting the expected productivity, itis either due to the inefficiency or the negligence of the management of those estates. All such estates have been established over75 years ago, after careful examination of their soil conditions and the rain fall distribution patterns etc by the RRI. Hence, if they have been properly managed, they should give good rubber yields even today. This is very clear from the lower productivity reported by these estates, compared to the small farms of small holders.

The presence of main plant nutrients, namely nitrogen, potassium, magnesium and phosphorous in the rubber harvested is insignificant, compared to any other agricultural crop, particularly palm oil. Further, during the wintering period rubber tree returns all nutrients back to the soil, and that is why rubber plantations are identified as the best replacement for rain forests. The situation with regard to oil palm is quite different. After two to three rounds of planting, the soil is depleted of all important nutrients, making the land unsuitable for any other crop.

Therefore, with better agricultural practices, such estates with low productivity could be converted to more productive and sustainable estates. If you take the example of Dartonfield estate where RRI is situated, which was one of the lowest yielding estates in the country in mid nineteen nineties and hence was not wanted by any private company to manage. When it was advertised there were no bidders to take over. But when the management of the estate was given to the scientists by the ministry, within eighteen months they were able to convert it into a profitable venture by tremendously increasing its productivity and by minimizing the tapping cost.

Any land in Sri Lanka so far unutilized for planting a crop, particularly marshy lands in very wet zone of the country, could be converted to oil palm to meet the edible oil shortfall and also to provide oil required for the soap industry etc.RRI will definitely provide their fullest corporation for that.

Plus factor

The only plus factor for oil palm over rubber as a plantation crop is its lower labour utilization. But, when all other factors are considered, rubber is a wonder crop for Sri Lanka plantations. Rubber trees provide fire wood requirement for tea drying and rubber drying, bakery industry brick lime and for tile industries. In such industries, particularly in the bakery industry.

If, other types of wood are used in bakeries, various flavours imparted to the bread by the firewood used make the bread unsuitable for consumption. Tea industry alone utilizes over 60 percent of the total rubber wood available annually. Even tile and brick makers prefer to use rubber wood in their furnace, because of the ability to control heat in the furnace when rubber wood isused, compared to other types of wood. Boron treated Rubber wood can be used to make furniture. In Malaysia, the income generated from rubber wood furniture and kitchen utensil export is higher than the income generated from rubber products export.

On the other hand what can you do with the trunk of oil palm? It can only be used to make the pestle (Molgas) for rice pounding. Rest of the trunk, when allowed to decay, breeds beetles that destroy coconut plantations. Effluent released by palm oil factories, which amounts to nearly 75 percent of the fruit weight, is one of the most difficult factory effluents to treat before discharging to lands. The effluent treatment is a problem in rubber industry too, but it is not as bad as in the case of oil palm. This palm oil effluent is virtually a poison for the dogs and birds.

The reason for not reaching expected yields in rubber estates is poor management practices, mainly not applying recommended fertilizer doses, and poor weed control. Fertilizer applications are not done according to recommendations because of the high cost. Fortunately, from last month, the price of urea and MOP, which are the two main components in a fertilizer mixture have been reduced by the government by over 40 percent. Therefore, now if the correct manuring is done, productivity of estates can be improved to reach at least the level of small holdings.

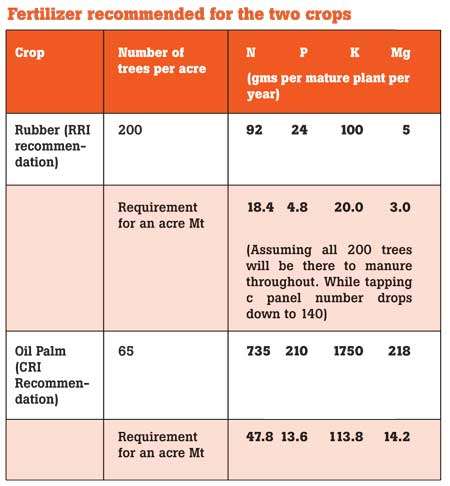

Those who promote replacing of rubber with oil palm should be aware that the fertilizer requirement for oil palm is much higher than the requirement for rubber, according to the recommendations of the respective research institutes; they are not equal based on the number of plants planted in an acre of land. Oil palm, only 65 per acre, while 200 rubber plants are planted per acre. But, when it comes to tap the c panel after 12 years`of tapping, number of trees needed to be manured drops down to about 140. Then can the little saving on labour and the slightly higher price of palm oil in the market offset the higher fertilizer cost? For your information I give below the amounts of nutrients recommended for the two crops by the respective research institutes.

From the given figures it is clear that the two major imported components Nitrogen ( N ) and Potassium (K) in the fertilizer recommended for oil palm is over two times and over five times more than the recommendation for rubber, respectively. That is assuming that all 200 trees will remain yielding throughout. But, RRI recommend only 140 trees need manuring while reaching the c panel after 12 years of tapping. The situation with regard to Phosphorous (P) and Magnesium (Mg) too are the same, but we need not bother too much about them as they are available locally. However, even Eppawala Rock Phosphate which is the local source of P, is price wise very close to the price of N and K fertilizers. At the price of fertilizer in the local market today, the cost of fertilizer per acre of oil palm for a year is over 4 times the cost of fertilizer for an acre of rubber.

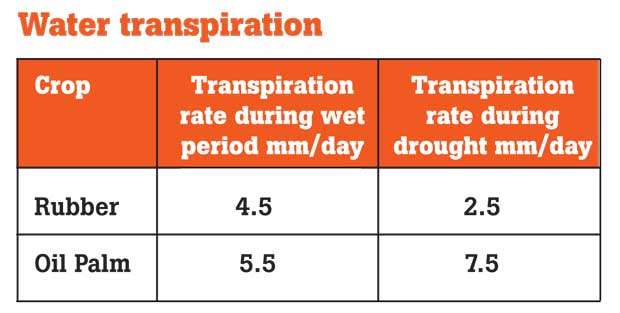

The main complaint of the villagers and the local government authorities in oil palm planted areas in Sri Lanka is that the traditional sources of water in those areas have gone dry after oil palm plantation. I am certain that there is some truth in this complaint because in Malaysia, due to the same reason, there is a restriction for planting oil palm in paddy cultivated areas of the country.

When internationally published water transpiration rates for the two crops are considered, during dry seasons the transpiration rate from oil palm trees rise up to 7.5 mm per day while the transpiration rate of rubber is reduced to a third of that, 2.5 mm per day.

According to hydrology experts who visited Sri Lanka in the past, when the forest reserves in the country have depleted to 16.5 percent, we get fair, but very uneven weather conditions in the country, thanks to 125000 Ha of rubber planted all over. They felt thatthe two rivers flowing down from Sripada, Kelani Ganga and Kalu ganga would have dried by now if not for the rubber plantations on either side of the two rivers, down from Sripada to at least Awissawella area.

Isn’t it unfortunate that we are going to sacrifice the rubber cultivations that provide a huge foreign exchange income to the country while providing employment to over250000 estate workers and about another30,000 skilled people of the country, purely to fill the shortfall of oil for all purposes, ignoring the ecological impact of this foolish crop diversification? If that happens arewe going to import drinking water too from South East Asia,along with ship loads of palm oil. Beware!

(The writer is a former Executive Director of the Rubber

Research Institute)

18 Nov 2024 2 minute ago

18 Nov 2024 9 minute ago

18 Nov 2024 1 hours ago

18 Nov 2024 1 hours ago

18 Nov 2024 2 hours ago