08 Jul 2021 - {{hitsCtrl.values.hits}}

Biotechnology as an industry in Sri Lanka has not progressed much further from curd and local alcohol. For the rest of the world, from early 1980s the term “biotechnology” did not simply mean the production of bread, cheese or wine using microorganisms

Sri Lanka already has the required human resources to carry out the biotechnology-based manufacturing processes. In fact, some of the life science degrees offered by our public universities are especially geared towards industrial biotechnology

What is biotechnology?

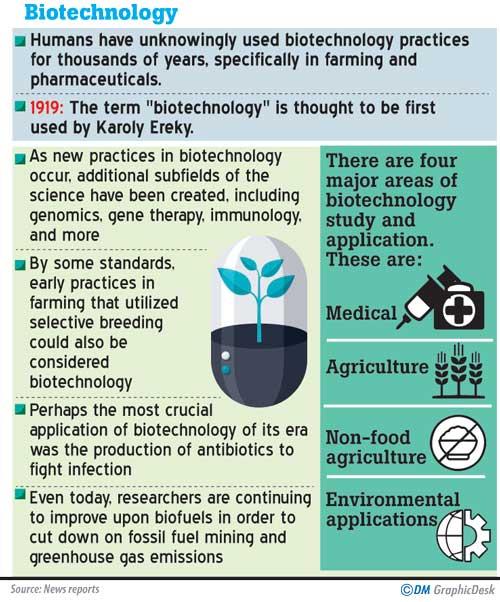

To explain in layman’s terms, biotechnology is a scientific discipline that is focused on harnessing biological organisms, biological molecules, or biological processes to produce commercially valuable products that can improve the quality of life by preventing or curing diseases, ensuring food safety, and providing clean energy.

Biotechnology has many applications in the health industry, food and agricultural industry and for the management of natural resources and the environment.

Though the term is relatively new to many, Sri Lankans have been using biotechnology for several years. For example, the fermentation of kithul or coconut treacle to produce “ra” or local alcohol is a biotechnology-based process because the fermentation process involves using wild yeast to convert the tapped treacle into an alcohol product. Our favourite dessert curd is also produced using a similar fermentation process, where bacteria are used to ferment buffalo or cow milk which results in the formation of curd.

Where does the Sri Lankan biotech industry stand?

But biotechnology as an industry in Sri Lanka has not progressed much further from curd and local alcohol. For the rest of the world, from the early 1980s the term “biotechnology” did not simply mean the production of bread, cheese or wine using microorganisms. It was the science of large-scale production of medicinally valuable human proteins (hormones, enzymes, antibodies), vaccines, antibiotics, dietary supplements, food additives, diseases resistant crop plants with enhanced yields.

The early years of biotechnology were dominated by a novl technology called recombinant DNA technology where a gene of interest copied from humans, or another species is inserted into the genetic material of a microorganism such as a bacterium, to mass-produce a valuable protein. In 1982, the federal drug administration (FDA) of the USA approved to use of human insulin produced in a bacterial species to treat type-I diabetes.

Previously insulin used for diabetes treatment was extracted from the pancreas of pigs and cattle, which was costly, and many patients had allergic reactions due to the animal origin of insulin.

This is a must-do for Sri Lanka, as equipment and instruments required for biotechnology product development are extremely costly and often biotechnology start-ups cannot shoulder these expenses. It would be well worth having laboratory spaces equipped with the necessary instruments into which start-ups can pay for their usage. This will boost research, development, and innovation in Sri Lanka in the field of biotechnology and long term would have a tremendous positive impact on the country’s economy

However, such allergic reactions were not observed for human insulin produced from bacteria using recombinant DNA technology and the production cost was also drastically reduced making insulin much more affordable. This marks the first time that the FDA has approved the use of a recombinantly produced protein as a therapy.

Ever since, many different recombinantly produced therapeutic proteins continued to enter the global health care market, not only improving the health and wellbeing of humans but also bringing in a large revenue to the manufacturers.

Shouldn’t we learn from our neighbour India?

The biotechnology industry of our closest neighbour, India is forecast to reach USD 150 million by the year 2025. It is already the home for more than 2000 biotechnology companies and more than 2500 biotech start-ups. It is the third-largest producer of hepatitis B vaccines in the world. The Serum Institute of India (Pvt) Ltd, which gained much attention throughout the world these days, including in Sri Lanka for its involvement in the production of AstraZeneca COVID-19 vaccine, produces many other vaccines including Polio, Diphtheria, Tetanus, Pertussis, BCG, Mumps, Measles, Hepatitis B, Rubella and Rabies. It is estimated that at least 65% of children in the world have received at least one vaccine sourced by the Serum Institute. India’s biotechnology industry presence in agriculture is strong too.

Currently, India has become the largest producer of genetically modified (GM) cotton (BT cotton) which shows remarkable resistance to insects that cause crop losses in wild type cotton. In the USA, about 8 genetically modified crops are grown commercially including corn, soybean, cotton, sugar beet and canola. Often these genetic modifications are to allow crops to become insect or herbicide-resistant, drought-tolerant or virus resistant.

The global GM crop and seed market is expected to value at USD 36 billion by the end of the year 2022. Scepticism regarding the long-term implications to the health and the environment from GM crops led multiple countries to put restrictions on the production and imports of GM crops. However, the United Nations, U.S. regulatory agencies such as the U.S. Department of Agriculture (USDA), the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) has approved a number of GM plants.

Modern biotechnology has expanded from simply using microorganisms or animal/plant cells to produce a target protein to modifying existing biological processes in microorganisms, animal or plant cells to transform cheap and renewable starting materials into a number of commercially valuable molecules.

For example, agricultural waste biomass such as rice straw, rice husks, wheat straw, sugarcane tops or molasses (a byproduct from the sugar refining process) can be transformed into bio-ethanol which is an alternative petroleum-based fuel. Danish biotech company called Inbicon showcased their ability to produce 1.4 million gallons of ethanol from 30,000 tons of straw. Brazil is a pioneer in ethanol production using sugarcane and supplies one-third of their fuel demand by blending bio-ethanol with petrol up to 24% (v/v).

Because bio-ethanol is a carbon-neutral energy source and reduces the dependency on fossil fuels it paves a way for nations to ensure energy security while addressing climate change. In the USA and Thailand, the percentage of ethanol in petrol blends is 10%, and in India, it is 5%. Implementing a similar policy in Sri Lanka mandating the use of ethanol-blended petrol could not only save millions of dollars spent on fossil fuel imports to Sri Lanka annually but also pave way for agricultural waste management, climate action and improved employment opportunities.

How is it more environmentally friendly?

Because biotechnology makes use of natural processes and renewable starting materials, they have far fewer effects on the environment than their chemical alternatives, leaves a smaller carbon footprint and fewer unwanted by-products while achieving high efficiency in target molecule production. Further, as these bio-transformations takes place at mild temperature conditions, it reduces energy consumption, water usage and manufacturing costs as well. Considering the positive economic output and sustainability of the biotechnology industry, biotechnology is highly likely the field that would allow many nations to achieve their sustainable development goals. While many developing nations have identified this, and hence, has invested and made progress in this field, Sri Lanka is unfortunately little less than half a century behind in realising this potential.

Why importing medicine when it can be produced here?

With the COVID epidemic ravaging the world, many pharmaceutical giants have expressed their willingness to transfer technologies associated with COVID vaccine production to vaccine manufacturing facilities throughout the world.

However, without any existing infrastructure (vaccine production facility) that could be diverted to produce COVID vaccines, we were unable to grab this opportunity and we are again waiting in line for vaccine stocks arriving from a production facility elsewhere in the world. Our local markets may be small, annually we may not require more than 500 000 polio shots and it may on the outside look profitable to import them. Each year many Sri Lankans rely on insulin injections to manage their Diabetes condition yet, only very recently investments were made to set up an insulin production facility in Sri Lanka. Many of the protein therapeutics discovered in the 80s, 90s and early 2000 have expired patents, meaning they can be reproduced without any legal obstacles. Some of these therapeutic proteins include widely used anti-cancer drugs such as anti-HER2 monoclonal antibody (trade name: Herceptin), anti-VEGF monoclonal antibody (Avastin), Erythropoietin (Epogen/Procrit) that is used to treat anaemic conditions resulting from chronic kidney disease, granulocyte colony-stimulating factor (GCSF) that is used to stimulate white blood production in bone marrow after chemotherapy, tissue plasminogen activator (Activase).

Without any existing infrastructure (vaccine production facility) that could be diverted to produce COVID vaccines, we were unable to grab this opportunity and we are again waiting in line for vaccine stocks arriving from a production facility elsewhere in the world. Our local markets may be small, annually we may not require more than 500 000 polio shots and it may on the outside look profitable to import them

International centre for genetic engineering and Biotechnology (ICGEB) -Biotechnology development unit has been a pioneer in assisting technology transfers of biotherapeutic products to its member countries, providing training, materials and facilitating quality assurance. Sri Lanka is one of its member countries and we should fully utilize their technology transfer facility to establish multiple biopharmaceutical manufacturing plants. Using a similar approach, establishing vaccine manufacturing facilities for the production of human vaccines that have expired patents through private or public-private investments is a need of the day. Another potentially profitable vaccine production venture would be the production of canine vaccines such as canine rabies vaccine, canine distemper, parvovirus vaccine.

What is Sri Lanka losing?

In long term, we are losing opportunities to enter the global market that would bring revenue to Sri Lanka along with opportunities to employ our highly skilled workforce who graduate with life-sciences degrees from our universities, and most importantly we are losing on setting a research and development landscape that could lead to breakthrough discoveries and innovations which can bring enormous revenue to the country.

Sri Lanka already has the required human resources to carry out biotechnology-based manufacturing processes. Some of the life science degrees offered by our public universities are especially geared towards industrial biotechnology. The University of Colombo offers highly specialized life sciences honours degree in Molecular Biology and Biotechnology especially targeting biotechnology industries. However, the lack of any advancement in the biotechnology industries in Sri Lanka has forced this highly skilled workforce to leave the country as they are preferentially recruited by global pharma and biotech companies like Gilead, GSK, Bayer etc. The University of Colombo also plans to establish a Bio-engineering department in the new Faculty of Engineering.

This addition would complete the entire skilled workforce required to operate bioreactor plants for large scale production of bio-therapeutics and other biotechnology-derived compounds. However, if steps are not taken to establish a diverse set of biotechnology industries through favourable policy changes and through investing via joint public-private partnerships we will certainly end up losing these highly skilled graduates to other countries along with great opportunities to generate a good income and sustainably develop our country.

What is the way forward for Sri Lanka?

So, what must be done, for us to tap into this vast potential in biotechnology? We need to look at what our closest neighbour, India is doing to promote Indian biotechnology industries. Policies play a pivotal role; India allows the construction of new production and operational facilities for pharmaceuticals and medical devices requiring minimum government approval (source: Indian brand equity foundation). Thus, adopting policies that promote investments in biotechnology industries (ease of establishment regulations, tax concessions for biotech industries etc.) and promote local usage of biotechnology products (ex. Bio-ethanol blended petrol and bio-diesel blended diesel) along with changing the current regulatory landscape to facilitate a fast-track approval process for biopharmaceuticals and diagnostics will certainly be a start for Sri Lanka. India also has a set up number of biotechnology parks equipped with instruments required for biotechnology-based product development.

These biotechnology parks offer facilities to scientists and enterprises for biotechnology-based product development and to conduct pilot plant studies to accelerate their commercialization. Further, these biotechnology parks provide seed funding, space and facilities and function as incubators for biotechnology start-ups, facilitating innovation among entrepreneurs.

This is a must-do for Sri Lanka, as equipment and instruments required for biotechnology product development are extremely costly and often biotechnology start-ups cannot shoulder these expenses.

It would be well worth having laboratory spaces equipped with the necessary instruments into which start-ups can pay for their usage. This will boost research, development, and innovation in Sri Lanka in the field of biotechnology and long term would have a tremendous positive impact on the country’s economy.

26 Nov 2024 3 hours ago

26 Nov 2024 4 hours ago

26 Nov 2024 5 hours ago

26 Nov 2024 6 hours ago

26 Nov 2024 7 hours ago