11 Jul 2016 - {{hitsCtrl.values.hits}}

July 1, 2016 can be considered an important milestone to both the shipping industry as well as to the international trade that deals with shipping. In reality, over 95 percent of world trade, especially with respect to movement of goods, takes place via the mode of sea transportation. Therefore, regulating maritime transportation would certainly overburden trade activities that already in place with the existing regulations of the international trade itself. However, maintaining safety of life at sea including that of protecting maritime transportation is equally important to upkeep that dangerous activity out of much risks. The following interview with Ceylon Shipping Corporation Executive Director Dr. Dan Malika Gunasekera is based on the recently enforced regulation on ensuring verified gross mass (VGM) in goods intended to be shipped on board vessels by shippers/exporters.

July 1, 2016 can be considered an important milestone to both the shipping industry as well as to the international trade that deals with shipping. In reality, over 95 percent of world trade, especially with respect to movement of goods, takes place via the mode of sea transportation. Therefore, regulating maritime transportation would certainly overburden trade activities that already in place with the existing regulations of the international trade itself. However, maintaining safety of life at sea including that of protecting maritime transportation is equally important to upkeep that dangerous activity out of much risks. The following interview with Ceylon Shipping Corporation Executive Director Dr. Dan Malika Gunasekera is based on the recently enforced regulation on ensuring verified gross mass (VGM) in goods intended to be shipped on board vessels by shippers/exporters.

What was the rationale in bringing this new regulation?

Shipping is a mode of transportation that dates back to many centuries. Although it wasn’t regulated in the history as much as it is now, 20th century lawmakers at international level have paid some  extensive attention to regularize the shipping sector considering devastating incidents that had occurred over the last few decades.

extensive attention to regularize the shipping sector considering devastating incidents that had occurred over the last few decades.

One may feel that the shipping sector is heavily regularized thus causing some negative impact on the trade, but ensuring safety of life at sea including that of the ships and their equipments including cargo of various owners is as similar to that of the trade. In view of the said, guaranteeing accuracy of the weight of cargo and containers was felt to be a necessary and integral element of ship safety.

Although this practice was ensured through representations in carriage documents such as bills of lading, there have been many instances where shippers were found to be guilty of alleged misstatement and misrepresentation. Over the years, we have seen many instances where maritime casualties both minor and major in magnitude became direct consequences of such inaccurate disclosure of container weights by shippers.

Throughout the past, it has been a common practice in shipping to issue transport documents such as bills of lading with some bold insertions like ‘said to contain’ in respect of the weight of cargo. Due to these irregularities, ships as well as cargo handling equipment at both loading and unloading ports such as gantries, cranes and forklifts became vulnerable to imminent danger thus causing them to collapse during handling of such over-weighed cargo that depicted false indications as to their weights.

Considering these scenarios, the International Maritime Organisation (IMO) through its Maritime Safety Committee took a decision to adopt Resolution MSC.380(94) on November 21, 2014 to amend the International Convention for the Safety of Life at Sea (SOLAS 1974). It is noteworthy that the SOLAS Convention has been ratified by 162 states representing a total of 98.77 percent of the World Merchant Shipping Tonnage.

By obtaining a container’s gross mass, which is the combined mass of a container’s tare mass and the masses of all packages and cargo items, including pallets, dunnage and other packing material and securing materials packed into the container, with a much responsible undertaking will certainly reduce risks for both the ships as well as to the handling terminals.

What changes has it brought to the existing situation?

What changes has it brought to the existing situation?

The 1991 Amendment to the SOLAS 1974 brought into being the much crucial change to its Chapter VI dealing with ‘Carriage of Cargoes and Oil Fuels’, in which, Regulation 1-2 is quite expressive in making proviso to guarantee the safe carriage of such cargo by requiring the contracting governments to ensure that ‘appropriate information on cargo and its stowage and securing is provided’.

Further modifications with respect to Regulation 2-1 on ‘Cargo Information’ were effected by subsequent amendment up to 2008 that required in particular the shipper to provide the master or his representative of the ship with appropriate information on the cargo sufficiently in advance of loading to enable the precautions which may be necessary for proper stowage and safe carriage of the cargo.

It further elaborated in Regulation 2-2 that such cargo should include information of it including among other things; the gross mass of the cargo or of the cargo units while Regulation 2-3 strictly required the shipper to ensure that gross mass of such units is in accordance with the gross mass declared on the shipping documents, prior to loading the cargo units on board ships.

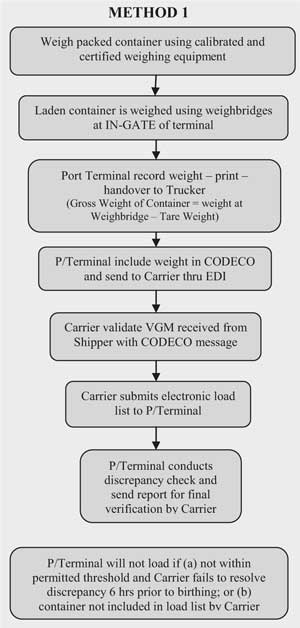

Much of the enthusiasm was placed upon the adoption of the recent Amendment that was brought into effect on this July 1, 2016, where it requires under Regulations 2-4.1 and 2-4.2, respectively, the exact verification of gross mass by the shipper himself. Accordingly, in the case of a full container load (FCL), weighing of the packed container is made mandatory using calibrated and certified equipment while in the case of loose container load (LCL), weighing of all packages and cargo items, including the mass of pallets and, etc.

How could this system of weighing packages through calibrated and certified equipment work?

First of all, calibrated and certified equipment as per the guideline regarding this matter means a scale, weighbridge, lifting equipment or any other device that is capable of determining the actual gross mass of a packed container or of packages and cargo items, pallets and, etc. As the cardinal obligation rests on the shipping administration of the country to maintain compliance with SOLAS regulations, it is the duty of the Director General Merchant Shipping (DGMS) to exercise his due diligence in relation to the related activities of the shipper, shipping line and the terminal operator.

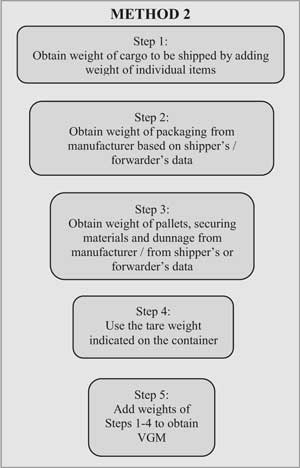

According to the guidance on the implementation of the SOLAS VI Regulation 2 amendment requiring the verification of the gross mass of packed containers issue by DGMS dated June 6, 2016 through Merchant Shipping Notice MSN 21/2016, the above said IMO Regulations 2-4.1 and 2-4.2 are referred to as Method 1 and 2, respectively. It clearly evidences that weighing used in Method 1 does not make much of complexities, but the Merchant Shipping Secretariat (MSS) will have to take extra precautions in approving certified methods in respect of Method 2.

It has been elaborated in its 5.4.1 that such approval could be granted either by being satisfied by the fact that the shipper has fulfilled the weighing requirement by way of obtaining the relevant document from a shipper’s business holding an accredited Quality Management System such as ISO 9001:2008 or 2015 by producing a copy of the granted MSS certificate or any other auditing schemes approved by the DGMS.

Furthermore, the actual accreditation process is detailed in Annex 2 to the said guidance. Interestingly, electronic transmission of the VGM certificates with electronic signatures would also be accepted by these authorities in allowing new technological developments to reap those benefits.

In making sure that the proper control and supervision exists with the shipping administration of the country while keeping the matters simple, 7.4 of the said guidance makes proviso in situations where cargo submitted and correctly marked is tendered by one Sri Lankan verified weigher to another Sri Lankan verified weigher for final loading – it will not be required to be reweighed prior to packing into the container, which is also considered as the ‘handshake’ principle. Nevertheless, the shipper of such goods will not be relieved of his liability as to the accuracy of VGS in such circumstances.

Do all types of cargo need to follow this requirement?

According to the SOLAS amended Regulation 2, not all container carriages have to undergo this procedure. Especially, the vehicle carriages that are engaged in Ro-Ro operations with containers carried on a chassis or trailer when they are being shipped in short international voyages need not require the meeting of this mandatory VGM procedure.

In terms of Hague-Visby Rules as applicable under the Carriage of Goods by Sea Act No. 21 of 1982, cargo that falls under its meaning would compatibly applicable without any further modifications and this VGM requirement would certainly assist cargo owners and carriers in minimizing disputes that may arise by virtue of bills of lading falling under such regime.

Furthermore, MSN 21/2016 indentifies two more instances where these regulations will not apply. Firstly, it will not apply to cargo items tendered by shipper to the master of the ship for packing into a container, which is already on its board, and secondly to offshore containers that consist of a portable unit specially designed for repeated use in the transport of goods or equipment to, from or between fixed and/or floating installations and ships.

How will this process practically take place?

The shipper must ensure that he obtain a weight certificate issued by a weigh station utilizing calibrated and verified equipment with respect to a packed container on the route from shipper’s origin to the port terminal unless in the case of separate and individual packages that fall under Method 2 mentioned above. In the latter case, the shipping documents must indicate the shipper’s approval number issued by the DGMS.

In accordance with Regulation 2-2.5 the shipper is obliged to state the VGM in the shipping document failing which a packed container shall not be loaded to the ship as required under Regulation 2-2.6. However, any discrepancy between the VGM of a packed container declared prior to verification and its VGM verified afterwards in terminal may only be allowed subject to a maximum permissible error which amounts to a +/- 5 percent or 1.0 ton when the weight is rounded off to the nearest half ton upwards.

In addition to the shipper’s documents, all trucks that carry the respective packed containers must carry a certified tare weight certificate for both the prime mover and the trailer separately as required by 8.3 of MSN 21/2016. In practice, it is expected to weigh all export laden containers using weighbridges at in-gates of the respective port terminal while the particular truck driver must have in his possession the valid weight certificates for the prime mover and the trailer and be ready to produce them to the terminal gate clerks.

One may encounter issues in how to practically weigh the packed containers under Method 1 as well as to obtain certificates and approvals under Method 2. Annex 3 of the MSN 21/2016 clearly describes its procedure. Accordingly, those who use Method 1 should obtain these services from weighing equipment owner who should obtain the necessary approvals for the process from the Measurement Units, Standards and Services Department of Sri Lanka that would approve the type of equipment in compliance for calibrated and verified.

Such equipment owner has the option to calibrate at any firm with ISO 17025 authorizations by the Sri Lanka Accreditation Board (SLAB). Those who are using Method 2 can fulfil the requirement by one of the three following processes; i.e. (1) use of Enterprise Resource Planning (ERP), Systems Application Products (SAP) or similar management processes which are traceable and audit based; (2) by physically weighing goods on calibrated and certified equipment in accordance with manufacturers’ recommended practices or appropriate ISO standards or (3) use equivalent or homogeneous good with a known weight per pallet in conjunction with the use of ERP and auditability.

However, these recent introduction of regulations seem to have overburdened the shippers/exporters at large. Not only them, but also the service providers such as trucks that operate their businesses at marginal profits have experienced a stiff competition in fulfilling the statutory requirements that have been imposed upon them. These scenarios have resulted from extra costs to be borne by those respective parties in obtaining certificates and approvals either on a shipment basis or as an annual fee.

Those who are not able to fulfil the necessary ISO standards required under Method 2 will certainly have to obtain those services through third party service providers at a cost while that extra cost becomes an additional expenditure thus reducing the exporter’s profit margin.

Nevertheless, considering the importance of protecting ships and ensuring safety of navigation, these measures seem to have no other alternative than adhering to these newly enforced international regulations for ship safety as well as the safety of port terminals and their cargo handling equipment. Any shipper failing to furnish the requisites and more specifically does not provide the VGM and that the master of the ship or his representative and the terminal representative have not obtained that VGM in order, such container will not be loaded to the ship as per the law.

25 Nov 2024 51 minute ago

25 Nov 2024 1 hours ago

25 Nov 2024 3 hours ago

25 Nov 2024 3 hours ago

25 Nov 2024 3 hours ago